Since WIP inventory takes up space and can’t be sold for a profit, it’s generally a best practice for product-based businesses to minimize the amount of WIP inventory they have on hand. WIP inventory management is a dynamic process that requires continuous monitoring and adjustment. Manufacturers who understand the importance of WIP inventory and optimize it effectively can remain competitive in the market and achieve long-term success. By managing WIP inventory effectively, manufacturers can improve their competitiveness, increase customer satisfaction, and ultimately, increase profitability. That’s why over 15,000 businesses globally trust us as their inventory management solution.

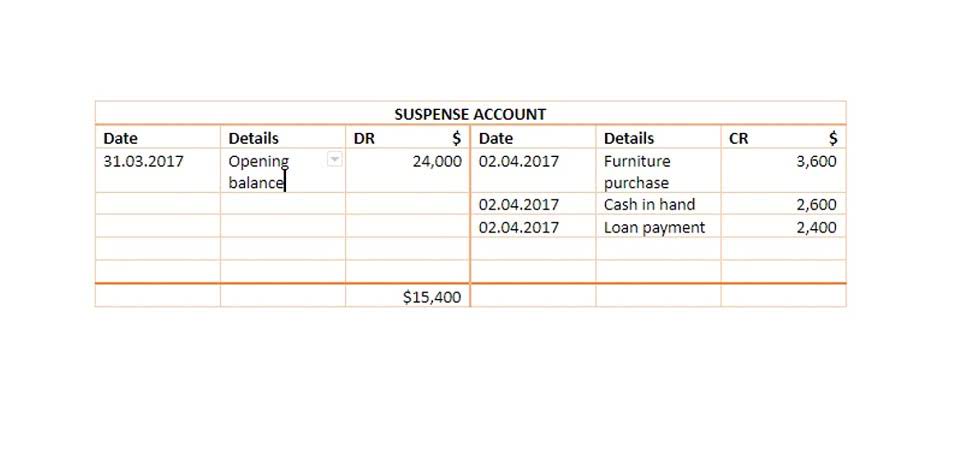

Turnover and Accounts Payable

Utilize the WIP inventory data to make informed operational and financial decisions. This information can be pivotal for optimizing production processes and managing costs effectively. Work in process (WIP) inventory is a term used to refer to partly finished materials within any production round. Work in process in production and supply chain management refers to the total cost of unfinished goods currently in production.

Aerospace Manufacturing Needs To Accelerate

Calculating the cost of WIP inventory is much more complex than calculating the value of the finished goods due to more intricate, moving parts. Here are some terms and calculations to achieve a better grasp of WIP inventory value. This article will dive into the basics of work-in-process inventory, including how to https://www.bookstime.com/articles/the-accounting-equation-may-be-expressed-as calculate the value of work-in-process inventory. Take your learning and productivity to the next level with our Premium Templates. Access and download collection of free Templates to help power your productivity and performance. It’s crucial to provide qualified workers with the appropriate tools and equipment.

Reduce costs

In both cases, a company develops an asset but the reporting and accounting treatment may vary. These goods are also referred to as goods-in-process, and for some, work in process refers to products that move from raw materials to finished products in a short period. An example of a work in process may include manufactured goods that take less than a full accounting cycle to normally complete. Thus, failing to account for it on your company’s balance sheet might result in an undervaluation of your overall inventory.

Work in process items usually transfer to inventory, then are used to determine cost of goods sold. Work in progress is usually reported as a capital asset and depreciated when completed. A significant WIP inventory level what is an example of work-in-process inventory for an automobile company? may indicate bottlenecks in your manufacturing process and that the process isn’t running correctly. With InventoryLogIQ, you can identify and fix these issues before they hurt your bottom line by tracking WIP.

The first step in optimizing WIP inventory is identifying production process bottlenecks. Bottlenecks are areas in the production process where production is slowed down or stopped due to a lack of resources or capacity. Manufacturers can adjust to optimize resources, reduce WIP inventory, and improve productivity by pinpointing bottlenecks. For example, if a particular work center is causing delays in the production process, manufacturers can allocate more resources to that work center to improve efficiency and reduce production time.

Benefits of POS Systems

- But in order to build the optimal inventory management system, you need the right tools.

- “Work In Process” typically is describing raw materials that are being converted to final goods during a relatively short time.

- The management examines this WIP level considering operational efficiency, storage costs, and production speed.

- By managing WIP inventory effectively, manufacturers can reduce production costs, improve productivity, and ultimately increase profitability.

- Inventory accounting works by tracking inventory costs and recording inventory assets and the overall value of inventory at the beginning and end of an accounting period to determine the metrics of a business.

When signs emerge that inventory data can’t be trusted, it’s best to do a physical inventory to correct the record. After this inventory, periodically doing cycle counts ensures that the records don’t deviate from the warehouse stock and stock on the shop floor. By monitoring the flow of materials and goods through the production process, manufacturers can identify bottlenecks, optimize production lines, and improve efficiency. WIP inventory can also help reduce the time it takes to produce finished goods, improving customer satisfaction and increasing sales. This account of inventory, like the work in progress, may include direct labor, materials, and manufacturing overheads. A company often uses internal allocation methods to determine the estimated financial value of work in progress.

Production Best Practices for Work-in-Process Inventory

- Lisa’s stock consists of 90 lipsticks, and by the end of the period, she sells 15 of them.

- Because it calls for an evaluation of the cost of labour and overhead related to the proportion of work completed, calculating WIP inventory is challenging.

- Work in process or WIP inventory refers to items in the manufacturing stage and being prepared to become a finished good for sale.

- Namely, inventory accounting allows businesses to assess where they may be able to increase profit margins on a product at a particular place in that product’s cycle.

- By identifying the root cause of the problem, manufacturers can take steps to optimize their production process, reduce WIP inventory, and lower production costs.

- By balancing workloads, manufacturers can reduce WIP inventory and improve productivity.

The fastest and most affordable strategy to reduce WIP is to keep equipment in good condition. Work-in-process inventory is also called work-in-progress inventory or WIP inventory. Now that you’ve got a grip on what WIP inventory is, you might be wondering why it’s important to classify in the first place. Diversity of thought, or cognitive diversity, encompasses varied perspectives and beliefs. If you need assistance with warehousing and fulfillment, partner with a 3PL that has the expertise, industry knowledge, and technology to help you make better business decisions.